Kinematic separator

Typ KS

Kinematic separators from HORSTMANN separate usable fractions from a wide variety of material mixtures for further processing in waste treatment plants. A combination of kinematic classifying and material screening is used to separate the material mixture into heavy fraction (3D), light fraction (2D) and a screening fraction.

The whole thing in just one operation!

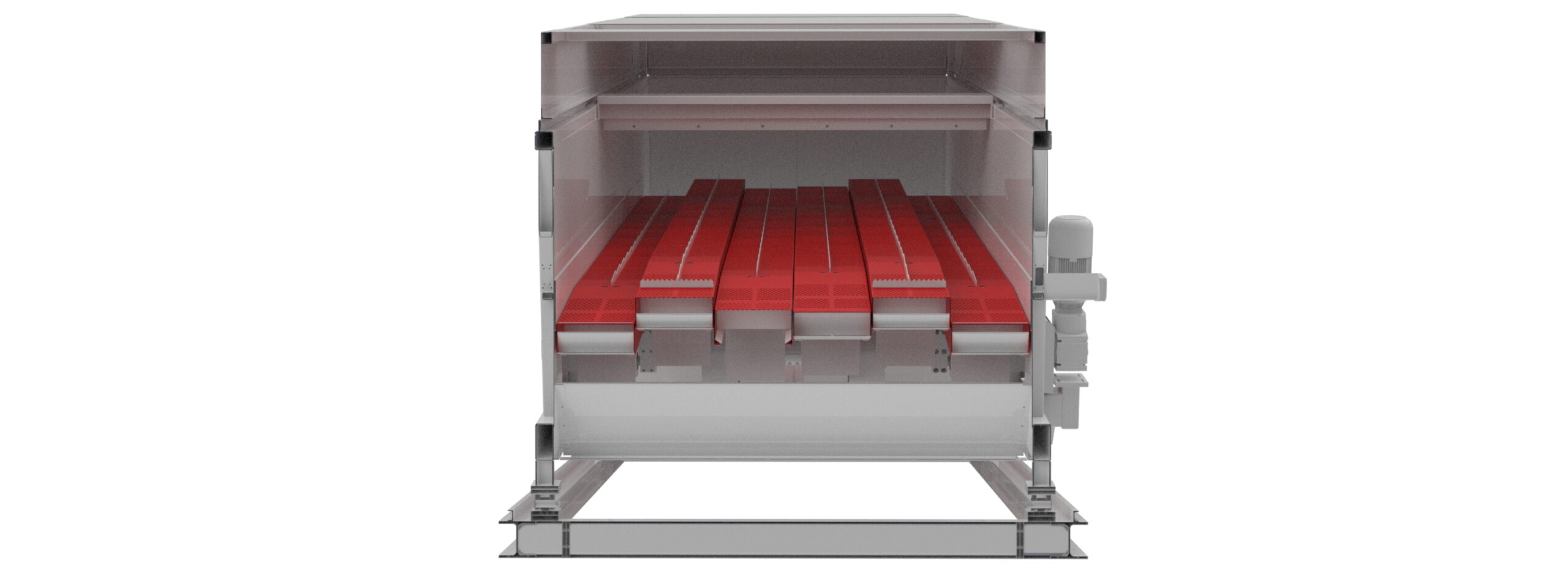

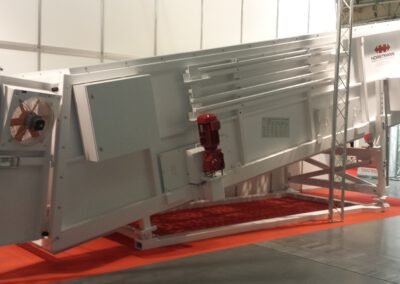

A suitable feeder is used to feed e.g. household, commercial or mixed construction waste to the machine, which is specially equipped for this purpose. In the classifier housing, the product falls onto an inclined, inclined plane, the sieve bottom. The split and movable screen units transport the material flow – depending on the specific weight and shape – up or down the level. The heavy components of the material, the heavy fraction (3D, rolling, heavy), slide to the lower end of the screen.

The light fraction (2D, flat, light) – cardboard, paper and foil – is transported by the movement of the screen plates, supported by air flow, to the higher end of the plane. The third fraction is created by the perforated screen units. These are easily interchangeable and their geometry determines the proportion of fractions screened. If required, the machine can also be equipped with an additional screening fraction. By adjusting the inclination of the machine, the proportion of light and heavy fraction can be adjusted to the bulk material. Depending on the application, the separator can be equipped from manual – to fully automatic adjustment. An efficiently working geared motor attached to the side outside the machine housing drives the sieve bottom crankshaft via a coupling and thus moves the sieve units offset to one another.

Alternative separation technologies, such as air classifiers with downstream screening, are often more cost-intensive in terms of investment and operating costs. Likewise, the space requirement is considerably more extensive.